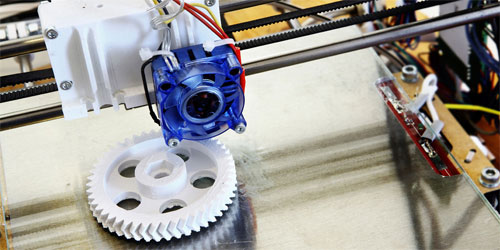

The problem with 3D printing is here now to be discussed.

There are several of things that are awesome about 3D printing. It gives us the potentiality to hold any level of complication. It ensures pinpoint accuracy. The things we can make are limited only by our thought. And it transported the promise of mass customization.

But I just don’t think it’s quite right. This technology was made-up to for bring revolutionary change in manufacturing. Put ingenuity and creativity in everyone’s hands. Interrupt the production model and a printer in every home.

Image Courtesy: manufacturing.net

Most people are still on the left side of the “hype curve,” on the peak of inflated hope, headed for the disappointment.

Jeff Kowalski, Chief Technology Officer, Autodesk said, he hasn’t given up, though. He continues trying keeping the promise, but released needs to start pushing past the promise stage for 3D printing to descend on the ground. To try and centering the problem, here are the top five lamentation with the current state of 3D printing. This blog originally appeared on Line/Shape/Space.

Image Courtesy: manufacturing.net

1. Output/Quality: This is the most basic thing, but there are many quality-related troubles with 3D printing today:

2. Fragile, delaminated FDM (fused deposition modeling) parts

3. Low-resolution output

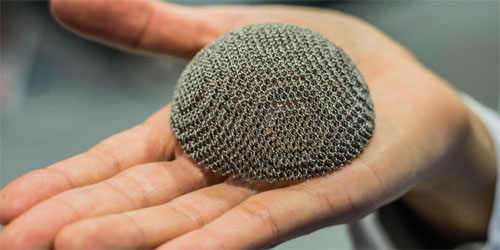

4. Materials: Now, to be fair, the materials are defined by what can be extruded, squirted, or melted, but this is not based on their application or final use. And even though there are some instances of multi-materials, it’s characteristically only two at a time.

But Kowalski don’t want to limit the imagination. He wants a printer that enables materials that didn’t exist outside of the printer. He wants one that makes metal alloys in the box.

Let me give you an example here. Which will either crystallize the problem or make you wonder how old Jeff Kowalski is: Remember Shrinky Dinks? You’d draw these designs, put them in the oven, reduce in size them, and then . . . understand the result wasn’t really worth having.

But here’s the point: Kowalski said, need to shift the emphasis in 3D printing from “Look, I made something!” to “Look what I made!” It has to be repetitive, high quality, using great materials, and producible in no other way.

The Printing Process Is Unreliable: The complicatedness of just getting the method to work is often intimidating, and it involves too much fraud with formats, parameters as well as mechanical modification.

You all know the joke by now:

- Why are 3D printers transparent?

- So you can watch your build fail!

- We can see what’s going on, but mostly it’s so we can interfere when the procedure breaks down.

It’s to the point where people put in cameras to watch their printers! Can you envisage standing there and staring at a 2D printer to confirm it was behaving properly? Of course it is not. It is time to shift from the fascination with 3D printers and 3D printing and focus on what is being 3D printed. Kowalski said: “Who cares if I have a great 3D printer, and I’m having a great time 3D printing? What I want is the output.”

Image Courtesy: manufacturing.net

Jeff Kowalski, actually look forward to the day when 3D printers are not transparent, but the path from design to fabrication is clear. When the whole procedure is so reliable and high quality that 3D printing experiences the wonderful fate of any victorious technology: ubiquity and invisibility. A boring, black box.

On the whole, the goal should be to move to “one-click-print” dependability. To get there, what’s needed is the equivalent of PostScript and the LaserWriter, which were the catalysts for dependable desktop publishing. That’s what it’s going to take to get some real traction on this “revolution.”

The Target: It’s Wrong: The fourth lamentation is that people have been aiming at the wrong target with their 3D-printing efforts.

They’ve been happy creating prototypes, replacement parts, and trinkets; but what they should be focused on is final parts and creating novel solutions to higher-level problems.

In order to reach this new goal, it’s vital to look at 3D printing holistically, through four different features of additive manufacturing:

- parts,

- system,

- materials, and

- process.

In other built-up processes, you could divide these four ideas and optimize each separately. But in 3D printing, they all come together because they all influence each other. The best way to achieve assembly function is through materials. Springs, levers, hinges, and dampers can be achieved, not just via individual parts, but also through intelligent in-process materials. Understanding the relationship between interacting elements is key.

Image Courtesy: manufacturing.net

The Market: It’s Prematurely Mature: Jeff Kowalski believes, last 3D-printing lamentation is that 3D-printer manufacturers seem to be hastily solidifying standards and stifling innovation. Today, the 3D-printing market is still “prematurely mature.”

Manufacturers are unluckily mistaking that smaller, earlier chasm for the bigger one ahead. Customers are the supportive, not the majority. Yet manufacturers are using business models meant to optimize later phases as if there were already a printer in every home.

But that’s passionate thing, because this is still the first phase, where open innovation should still be major. Instead, you see manufacturers put ID chips in material cartridges, so they can’t be refilled or sourced to a different place.

Doing that gets you enthralled with material sales, and then you start doing dumb things like overprinting support materials, as opposed to addressing the real customer need, which is that they don’t want hold materials at all!

Thinking like this brings you to a stalemate condition because you put the business ahead of the customer. Everybody must agree that the industry is not done any innovation yet.

So here are Jeff Kowalski’s five lamentations and their potential cures summed into one sentence: Designers require solving problems with new solutions, less effort, more results, greater expression, increased reliably and confidence, and good quality.

- Cover Story

-

SketchUp Can Help You Win Interior..

SketchUp Can Help You Win Interior.. -

Best Laptops for SketchUp

Best Laptops for SketchUp -

How to Resize Textures and Materials..

How to Resize Textures and Materials.. -

Discovering SketchUp 2020

Discovering SketchUp 2020 -

Line Rendering with SketchUp and VRay

Line Rendering with SketchUp and VRay -

Pushing The Boundary with architectural

Pushing The Boundary with architectural -

Trimble Visiting Professionals Program

Trimble Visiting Professionals Program -

Diagonal Tile Planning in SketchUp

Diagonal Tile Planning in SketchUp -

Highlights of some amazing 3D Printed

Highlights of some amazing 3D Printed -

Review of a new SketchUp Guide

Review of a new SketchUp Guide

- Sketchup Resources

-

SKP for iphone/ipad

SKP for iphone/ipad -

SKP for terrain modeling

SKP for terrain modeling -

Pool Water In Vray Sketchup

Pool Water In Vray Sketchup -

Rendering Optimization In Vray Sketchup

Rendering Optimization In Vray Sketchup -

Background Modification In sketchup

Background Modification In sketchup -

Grass Making with sketchup fur plugin

Grass Making with sketchup fur plugin -

Landscape designing in Sketchup

Landscape designing in Sketchup -

Apply styles with sketchup

Apply styles with sketchup -

Bedroom Making with sketchup

Bedroom Making with sketchup -

Review of Rendering Software

Review of Rendering Software -

Enhancing rendering for 3d modeling

Enhancing rendering for 3d modeling -

The combination of sketchup

The combination of sketchup -

Exterior Night Scene rendering with vray

Exterior Night Scene rendering with vray