The 3D printing has its roots in the 1980s. In 1984, Chuck Hull, invented a process called ‘stereolithography’ which used UV lasers to solidify photopolymer that made 3D parts layer by layer. In 1985, Materialise CEO Fried Vancraen was a young man making his own non-computer ‘FDM’ models. Five years later, he founded Materialise, one of the first 3D printing companies.

Taking its roots in manufacturing, 3D printing was primarily used for prototyping products. In fact, large corporations continue to use rapid prototyping to save millions of dollars. For example, Ford is currently using 3D printing to make large selections of its car parts for testing. According to Ford, the company can save up to $493,000 a month of work with this production method. And now, we see that designers and individuals worldwide are also turning to 3D Printing to bring their own creations to life, both for personal use and for the enjoyment of others.

Additive manufacturing (AM) or 3D printing works a lot like your inkjet printer at home. The ink jet printer puts a single layer of ink on top of the page in order to get the job done, while a 3D printer adds new layers on top of each layer before it, until the object is completed. Because of this layer-by-layer printing process, an escape hole is usually necessary to properly print and clean your models.

Since the 80s, many new materials for 3D printing have entered the market, including gold, silver, concrete, and various other metals. Over the last year alone we have seen 3D printed houses, drones, dresses, jewelry and table wear being printed. You might’ve heard about 3D printed prosthetics used to treat wounded soldiers too! But, scientists are currently working on new, bigger projects. They are hard at work perfecting the next generation of 3D printed materials. One day, we may even see 3D printed organs!

Traditional manufacturing models require a lot of upfront costs, storage fees and uncertainty from investors. Machines have to be set up, space rented, and fingers crossed that the manufactured product sells. 3D printing takes a more fluid approach: you can print orders on-demand. If you’re a maker or an entrepreneur trying to get a small business off the ground, this can home in handy. The additive process wastes very little material and you can print as the orders come in. This makes it less financially risky and translates into a low cost of production.

3D printing is already being used in movies. Props can take hours of hard work to create and apply. With 3D printing, many of those props can be created and re-created faster, easier, and without starting from scratch. 3D printing techniques have been featured in movies such as IronMan, The Hobbit, Jurassic Park, Avatar, The Muppets, Terminator Salvation, Real Steel, Paranorman, The Avengers and Paranorman.

NASA researches are currently working on figuring out how to bring 3D printing technology to space. The idea is to send robots ahead of astronauts to construct buildings and infrastructure on lunar surfaces. 3D printing is a growing training area in schools, and is also being used to integrate students with disabilities in programs that has traditionally excluded them (and often still does.) Personalized, 3d printed medical solutions can empower a person with arm injuries to become a musician, a person without legs to play soccer, and students who are blind to “see” microscope slides.

For younger students, art, design, entrepreneurship and engineering are unlocked with increasingly simple 3D modeling tools. These tools empower children to turn their ideas into objects they can hold. The first community college in Texas is now offering 3D printing classes this fall and educational programs are available for those wanting to introduce the biomedical applications of this technology into their curriculums.

- Cover Story

-

SketchUp Can Help You Win Interior..

SketchUp Can Help You Win Interior.. -

Best Laptops for SketchUp

Best Laptops for SketchUp -

How to Resize Textures and Materials..

How to Resize Textures and Materials.. -

Discovering SketchUp 2020

Discovering SketchUp 2020 -

Line Rendering with SketchUp and VRay

Line Rendering with SketchUp and VRay -

Pushing The Boundary with architectural

Pushing The Boundary with architectural -

Trimble Visiting Professionals Program

Trimble Visiting Professionals Program -

Diagonal Tile Planning in SketchUp

Diagonal Tile Planning in SketchUp -

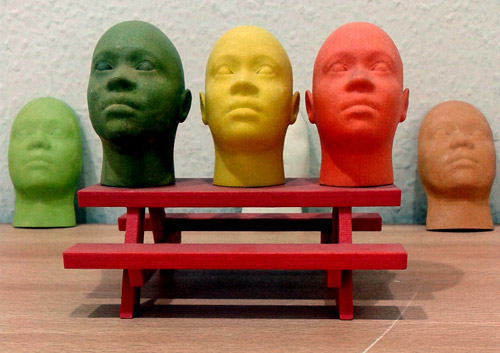

Highlights of some amazing 3D Printed

Highlights of some amazing 3D Printed -

Review of a new SketchUp Guide

Review of a new SketchUp Guide

- Sketchup Resources

-

SKP for iphone/ipad

SKP for iphone/ipad -

SKP for terrain modeling

SKP for terrain modeling -

Pool Water In Vray Sketchup

Pool Water In Vray Sketchup -

Rendering Optimization In Vray Sketchup

Rendering Optimization In Vray Sketchup -

Background Modification In sketchup

Background Modification In sketchup -

Grass Making with sketchup fur plugin

Grass Making with sketchup fur plugin -

Landscape designing in Sketchup

Landscape designing in Sketchup -

Apply styles with sketchup

Apply styles with sketchup -

Bedroom Making with sketchup

Bedroom Making with sketchup -

Review of Rendering Software

Review of Rendering Software -

Enhancing rendering for 3d modeling

Enhancing rendering for 3d modeling -

The combination of sketchup

The combination of sketchup -

Exterior Night Scene rendering with vray

Exterior Night Scene rendering with vray